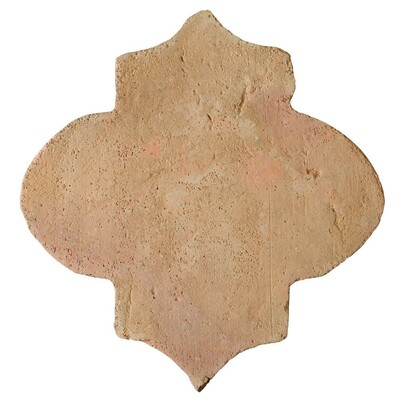

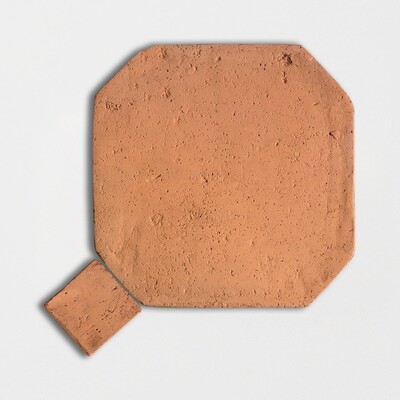

Cotto Med Matte Cornice Terracotta Moldings

ITEM CODE:

ML90158STOCK:

849.00 pcsWEIGHT:

1.37 lbs / pcs- Sample discounts are only for samples and cannot be applied to material orders.

- Please note that all sample orders are processed and shipped in 5-10 business days plus shipping time.

- Quantities available is subject to material in transfer, transit and prior sale. Please call your branch to confirm availability.

- This Item is produced regularly. Please inquire for additional production information.

Natural stones are products of nature, and no two pieces are exactly alike. These codes are intended as a general guide to how much variation in color, movement, and veining can be expected. All natural stones have unique natural variations and inclusions that are impossible to show in a photograph or sample. For this reason, all stone should be unpacked and inspected prior to installation, as Marble Systems cannot accept claims for variation in any stone after install.

- Some Medium and Heavy Duty stones cannot be used in exterior applications in areas that experience freeze/thaw conditions. Please use specific stone in the Usage Guide for this information.

- Some Medium Duty stones may be subject to scratching or etching when used as countertops.

- Light, Medium and Heavy Traffic refer to pedestrian traffic only. If the stone is to be installed in an area with vehicular traffic, please contact a sales representative to inquire about thickness and installation requirements.

- Stone in this group must be sealed periodically as a normal maintenance routine if used in wet areas.

- These materials may contain areas of open or dry seams that can appear dull in reflective light. This is not a defect, but rather an inherent characteristic of the stone.

- White thin-set or mortar is required. This is the case for all limestone, tumbled stones, “antiqued stones” and light color marbles.

- These stones may be characterized by dry seams, pits, and fossils. In polished and honed stones, these areas are often filled at the factory. In rustic or tumbled stones, as well as with some honed limestone, these are often filled with grout during installation. Whether filled at the factory or during installation, the fill can work its way out of the voids. In these instances, it may be necessary to refill these voids as part of a normal maintenance routine.

Get the most out of your Marble Systems product by following these helpful instructions for installing floor tile. A Few Dos & Don’ts

- Tile may be installed over most structurally sound substrates if they are clean, smooth, dry and free of wax, soap scum and grease and other debris.

- Carefully read and follow all instructions and precautions on the adhesive or mortar package. Mix only enough to be used within 30 minutes.

- Since variation of shades is an inherent characteristic of ceramic tile, mix tiles from several cartons as you set, for a blended effect.

- Order extra material for cuts, spare tiles, and waste.

- If material is face taped, remove tape after installation.

- Be sure to calculate exact tile needed for your surface before installation.

- If you are short of material do not start installation until you have all the tile that blends. Additional shipments may not match the tile from previous shipment.

- If you do order additional tile for an older job be sure to match color lots before installation.

Tile may be installed over most structurally sound substrates, if they are clean, smooth, dry and free of wax, soap scum and grease. Any damaged, loose or uneven areas must be repaired, patched and leveled. Remove any moldings, trim, appliances, etc., which could interfere with installation. Door jambs may be undercut for tile to slip under. We recommend waterproofing most floors to prevent surface seeping.

Begin by marking the center point of all four walls. Snap chalk lines between the center points of opposite walls, which will intersect at the center of room. Make sure they›re perfectly square, and adjust if necessary. Next, lay out a row of loose tiles along the center lines in both directions, leaving spaces for uniform joints (use tile spacers). If this layout leaves cuts smaller than 1/2 tile at walls, adjust the center line by snapping a new line 1/2 tile closer to the wall. Repeat along other center line if necessary. Now divide the room into smaller grids (approx. 2' x 3') by snapping additional lines parallel to center lines.

Select the right adhesive for the substrate you're using. Carefully read and follow all instructions and precautions on the adhesive or mortar package. Mix only enough to be used within 30 minutes. Using the type of trowel recommended on the adhesive package spread a 1/4" coat on the surface of one grid area, using the flat side of the trowel. Do not cover guidelines. Next, use the notched side of trowel to comb adhesive into standing ridges by holding trowel at a 45-degree angle. Then remove excess adhesive, leaving a uniform, ridged setting bed. Don't spread a larger area than can be set in 15 minutes.

We recommend using white good quality thin set such as Mapei, Laticrete, or Ardex.

Some black marbles, white marbles, dolomites, and green marbles may have to be installed with Moisture sensitive thin set. Please check with the manufacturer.

Carefully measure tiles to be cut and mark with a pencil or felt-tip pen. Make straight or diagonal cuts with a tile cutter, curved cuts with a nipper (chipping away small pieces for best results) and full-length curved cuts with a rod saw. Sharp-cut edges may be smoothed with a carborundum stone.

Variation of shades is an inherent characteristic of marble, stone and ceramic tile – mix tiles from several cartons as you set, for a blended effect. Begin installing tiles in the center of the room, one grid at a time. Finish each grid before moving to the next. Start with the first tile in the corner of the grid and work outward. Set tiles one at a time using a slight twisting motion. Don't slide tiles into place. Insert tile spacers as each tile is set, or leave equal joints between tiles. Fit perimeter tiles in each grid last, leaving 1/4" gap between tile and wall. Any rectangle porcelain should never be set in a running bond pattern, rather no more than a 1/3 overlap; the joint should be widened to 3/16" and use of a large unit porcelain mortar should be employed. When grid is completely installed, tap in all tiles with a rubber mallet or hammer and wood block to ensure a good bond and level plane. Remove excess adhesive from joints with a putty knife and from tile with a damp sponge. Do not walk on tiles until they are set (usually in 24 hours).

Generally, you should wait about 24 hours before grouting (refer to the adhesive package for specifics). Carefully read and follow all instructions and precautions on the grout package. Make only enough to use in about 30 minutes. Remove tile spacers and spread grout on the tile surface, forcing down into joints with a rubber grout float or squeegee. Tilt the float at a 45-degree angle. Remove excess grout from surface immediately with the edge of float. Tilt it at a 90-degree angle and scrape it diagonally across tiles. Wait 15-20 minutes for grout to set slightly, then use a damp sponge to clean grout residue from surface and smooth the grout joints. Rinse sponge frequently and change water as needed. Let dry until grout is hard and haze forms on tile surface, then polish with a soft cloth. Rinse again with sponge and clean water if necessary. Wait 72 hours for heavy use. Don't apply sealers or polishes for three weeks, and then only in accordance with manufacturer's recommendations.

For travertine tiles, materials with holes, aqua forte etc. use a grout release before grouting. You can also a sealer before grouting. This will help you clean the grout easier.